- All

- Product Management

- Blog

- Introduction

- Corporate Outlets

- FAQ

- Corporate Video

- Corporate Brochure

Exciting News | AihyTech's 'Low-Iridium High-Current-Density PEM Hydrogen Production Electrolyzer' Selected for Fujian Province Energy Sector Energy-Saving New Product Promotion Catalogue! Only Four Items in the Province!

Release time:

2024-12-27 16:05

Source:

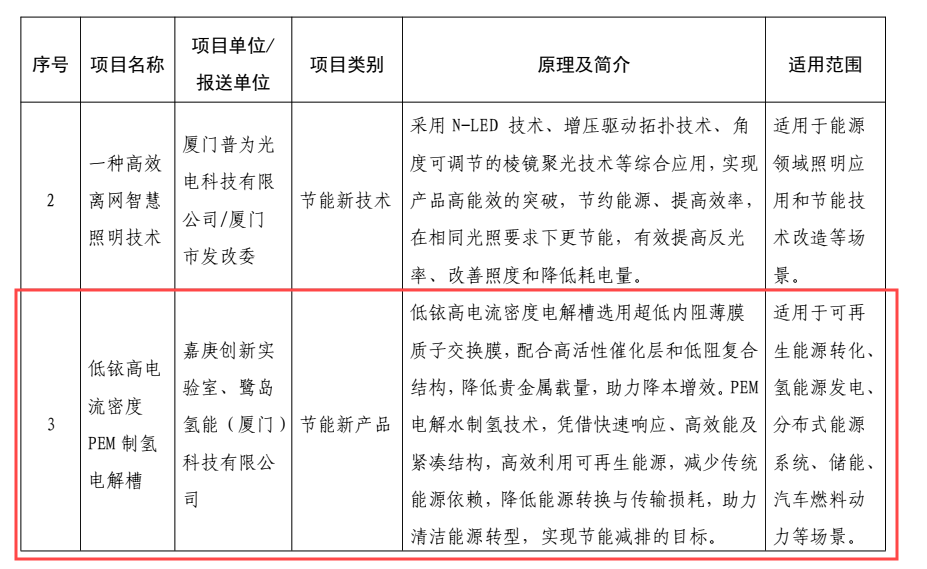

On December 20, 2024, AihyTech's core product, the 'Low-Iridium High-Current-Density PEM Hydrogen Production Electrolyzer,' was officially included in the Fujian Province Energy-Saving New Technologies, Products, and Equipment Promotion Catalogue. This marks a significant achievement, as only four items were selected nationwide.

In June 2024, AihyTech actively responded to the 'Dual Carbon Strategy' by submitting its core product, the 'Low-Iridium High-Current-Density Electrolyzer,' for inclusion in the Catalogue. After undergoing a rigorous review process, including preliminary screening, presentation, and on-site inspections, the product demonstrated outstanding technological innovation and significant energy-saving and emission reduction effects. It aligned closely with the Catalogue's requirements and received high praise from the evaluation panel. Following a six-month comprehensive assessment, the product ultimately stood out and was successfully selected.

(Fujian Provincial Development and Reform Commission website notice: http://fgw.fujian.gov.cn/zfxxgkzl/zfxxgkml/yzdgkdqtxx/202412/t20241223_6596622.htm)

"Selected Product: Low-Iridium High-Current-Density PEM Hydrogen Production Electrolyzer"

The low-iridium high-current-density PEM hydrogen production electrolyzer is engineered with high-activity catalysts for harsh operating conditions and high-efficiency mass-transfer catalytic layers. It achieves leading electrochemical performance (2.5 A at 1.8 V) with the lowest iridium loading in the industry (0.4 mg) , ensuring performance while optimizing costs and improving efficiency. This product is widely applicable to renewable energy-based hydrogen production, distributed energy systems, and energy storage.

PEM water electrolysis technology utilizes its rapid response characteristics, high energy efficiency, and compact design to efficiently leverage renewable energy, reduce reliance on traditional energy sources, and minimize energy conversion and transmission losses. This innovation accelerates the transition to clean energy and supports the achievement of energy-saving and emission reduction goals.

Amoy Island Hydrogen (Xiamen) Technology Co., Ltd.

In recent years, AihyTech has achieved significant success through its strong R&D capabilities and industrialization expertise in PEM water electrolysis technology. The company's core product, high-performance PEM electrolyzers, offer a hydrogen production capacity range of 0–500 Nm³/h and include advanced electrochemical testing instruments. Its independently developed low-iridium high-current-density PEM electrolyzer has been recognized as 'First-of-its-Kind Major Technological Equipment in the Energy Sector' by the National Energy Administration and has been deployed in multiple renewable energy-based hydrogen production projects. With a full-cycle industrial chain for core materials and PEM hydrogen production equipment, AihyTech is highly regarded for its technological innovation and industry leadership.

In the future, AihyTech will steadfastly focus on advancing PEM water electrolysis technology, proactively addressing national key needs, and making significant contributions to energy-saving and emission reduction efforts, as well as the realization of the Dual Carbon Strategy goals.

Room 701, Building 666-1, Lianxiang Road, Xiang'an District, Xiamen City

Copyright © 2023 Amoy Island Hydrogen Technology Co., Ltd.

Website Construction:China Enterprise Power Xiamen | SEO