- All

- Product Management

- Blog

- Introduction

- Corporate Outlets

- FAQ

- Corporate Video

- Corporate Brochure

Company News | AihyTech's Low-Iridium, High-Current Density Single-Stack 500 Standard Cubic PEM Electrolyzer Officially Released

Release time:

2024-10-19 14:39

Source:

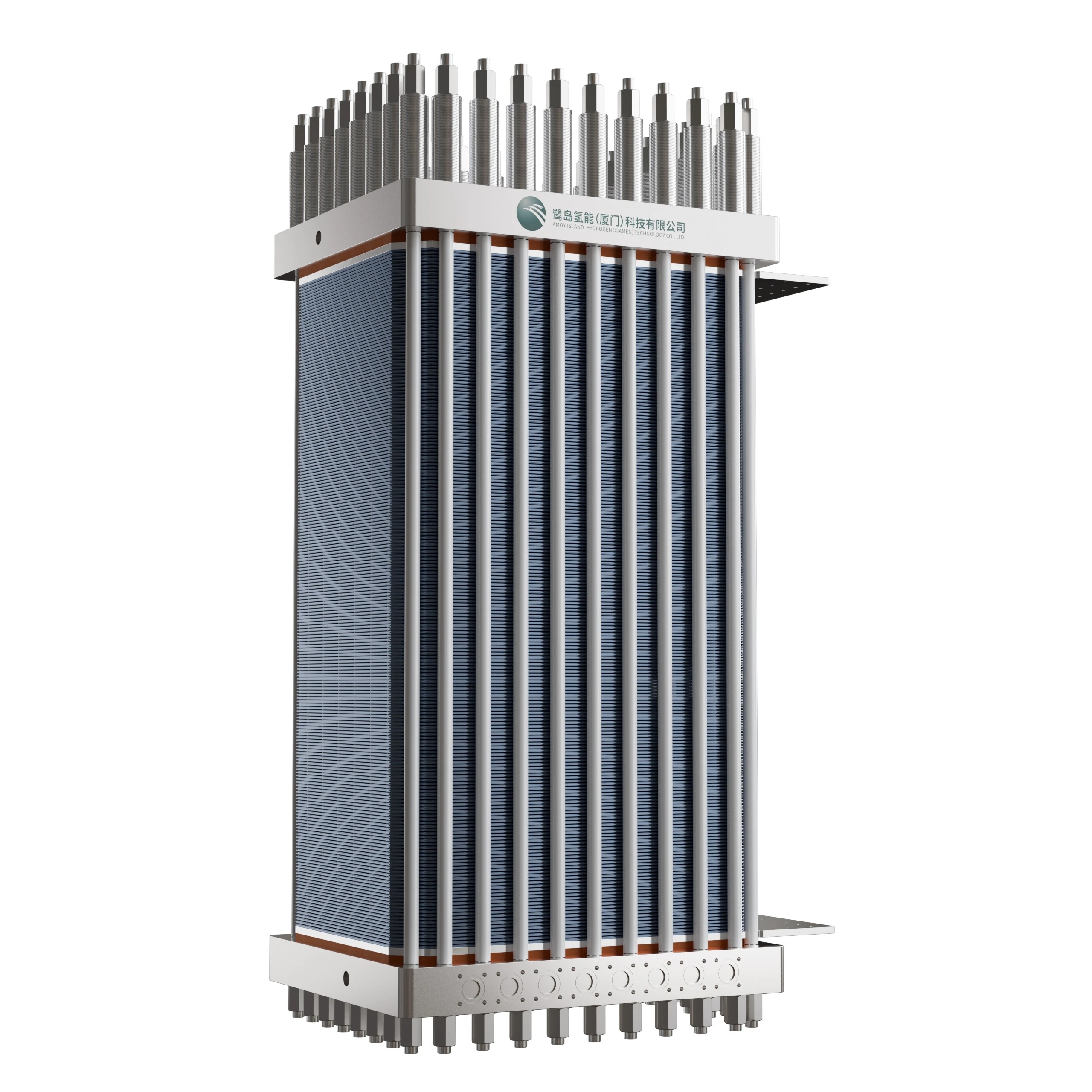

On October 19, Amoy Island Hydrogen Technology Co., Ltd. (hereinafter referred to as "AihyTech") independently developed a low-iridium, high-current density single-stack 500 Nm³/h PEM electrolyzer was officially released.

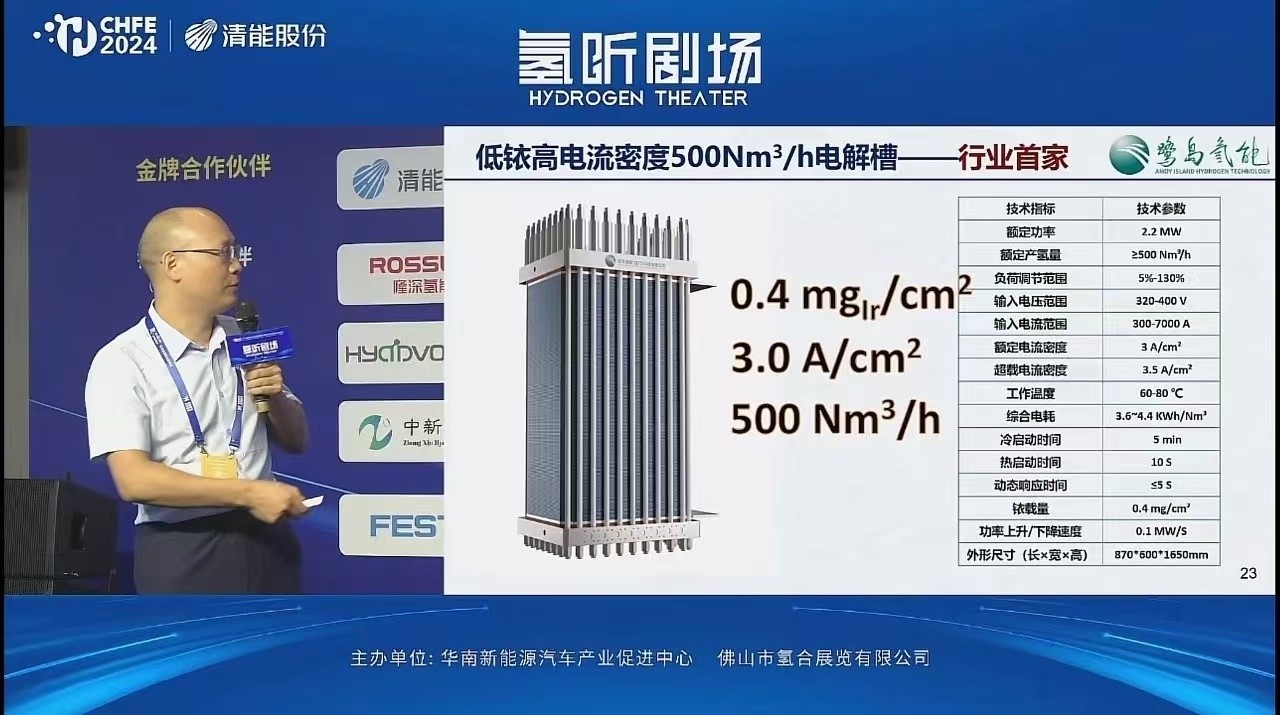

The new product adopts a number of AihyTech's advanced technologies, making significant breakthroughs in core materials and electrolyzer processes, with three highlights that are noteworthy:

Highlight 1: Single-stack breakthrough of 500 Nm³/h

Previously, the maximum hydrogen production of the low-iridium, high-current density PEM electrolyzer single-stack was 200 Nm³/h. Large-scale hydrogen production often required multiple electrolyzers to operate together. The 500 Nm³/h single-stack electrolyzer launched by Amoy Island Hydrogen this time can better meet the needs of large-scale hydrogen production, which is a significant breakthrough for this series of PEM electrolyzers and hydrogen production systems entering the large-scale era and also strongly promotes the greater role of domestic green hydrogen technology, especially PEM hydrogen production technology, in the hydrogen energy industry.

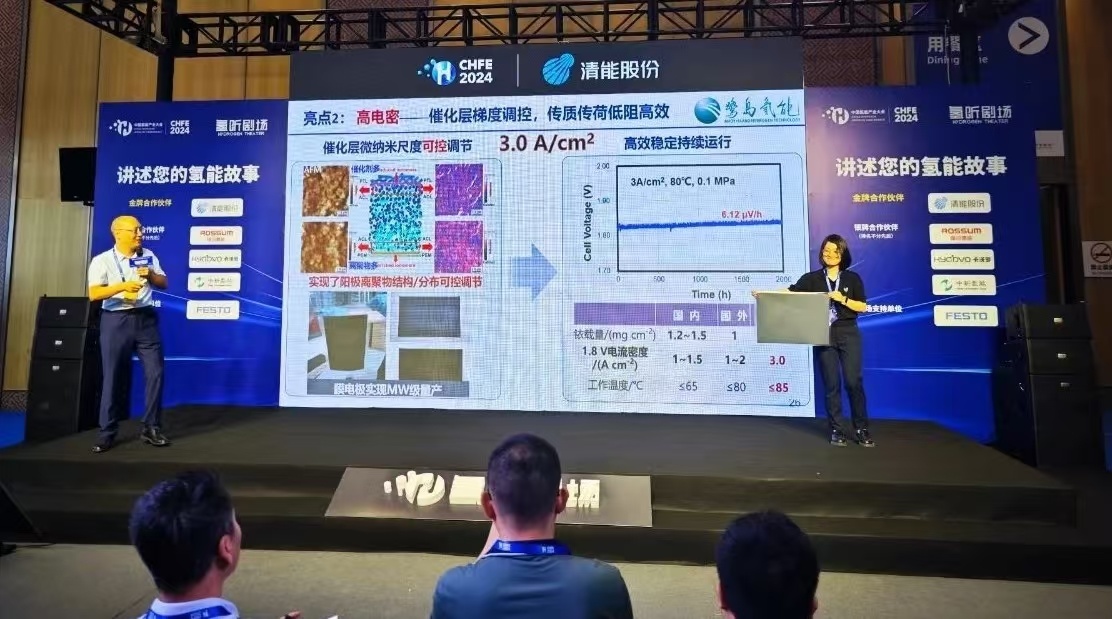

Highlight 2: Leading performance

The new product has a DC power consumption of 4.4 kWh/Nm³ at rated power, reaching the international first-class energy efficiency voltage level, with a current density of 3 A/cm² (leading the industry by 1-2 A/cm²), and an iridium loading of only 0.4 mg/cm² (lower than the industry level of 1 mg/cm²), with a load adjustment range of 5%-130% adapting to hydrogen production from renewable energy fluctuations under various conditions. In addition, the new product uses a new process, and the overall cost is reduced by a certain percentage compared to the 200 Nm³/h PEM electrolyzer in the same series, 30% is the latest work of Amoy Island Hydrogen's low-iridium, high-current density series electrolyzers that is efficient, low-cost, and worry-free.

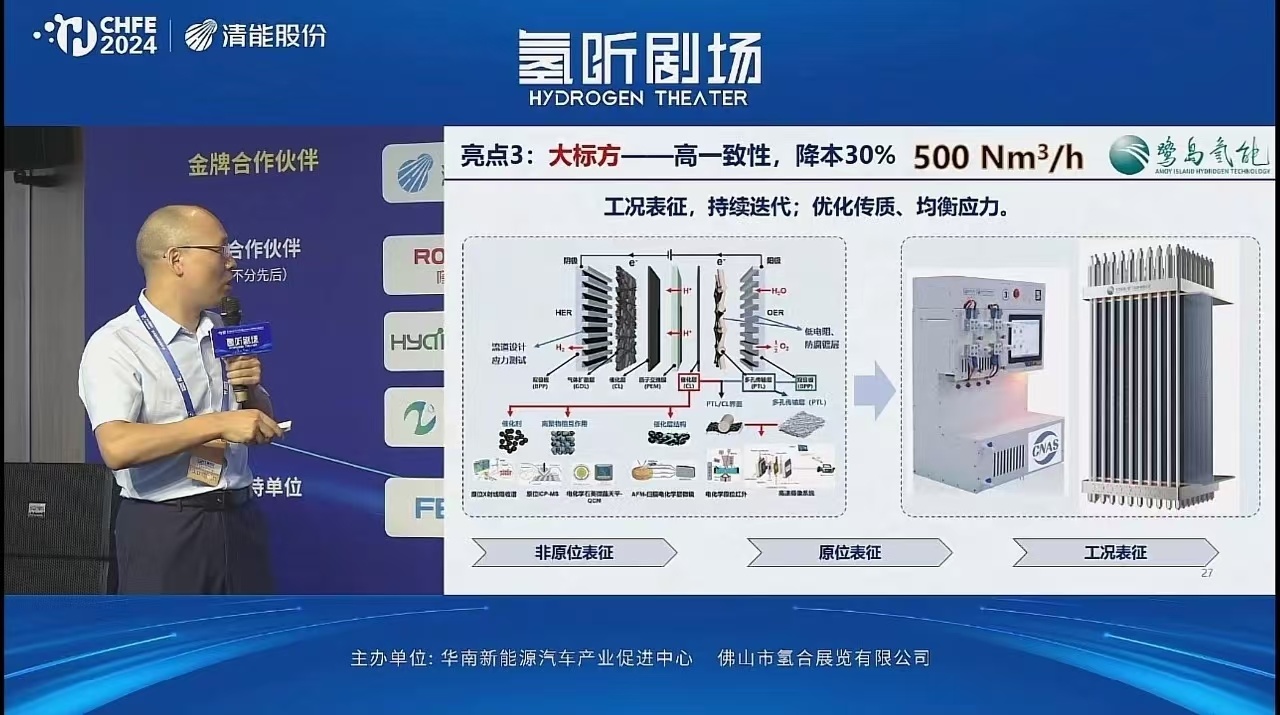

Highlight 3: Completely independent research and development

The new product was completely independently developed by the company, and the related inventions and patents are 100% owned by the company 100% owned. The localization rate of various components exceeds 90% ( key components achieve 100% independent production), and both technology and materials are independently controlled, avoiding the risk of core technologies being "stuck" by foreign countries, laying a solid foundation for the company's future product production and sustainable development.

Schematic diagram and technical parameters of the low-iridium, high-current density 500 Nm³/h PEM electrolyzer

| Technical Indicators | Technical Parameters |

| Rated Power (MW) | 2.2 |

Rated Hydrogen Production (500 Nm³/h) | ≥500 |

| Load Adjustment Range (%) | 5-130 |

| Input Voltage Range (V) | 320-400 |

| Input Current Range (A) | 300-7000 |

| Rated Current Density (A/cm²) | 3.0 |

| Overload Current Density (A/cm²) | 3.5 |

| Operating Temperature (℃) | 60-80 |

| Overall Power Consumption kWh/Nm³ | 3.6-4.4 |

| Cold Start Time (min) | 5 |

| Hot Start Time (S) | 10 |

| Dynamic Response Time (S) | ≤5 |

| Iridium Loading (mg/cm²) | 0.4 |

| Power Rise/Fall Rate (MW/S) | 0.1 |

| Dimensions (Length × Width × Height) (mm) | 870*600*1650 |

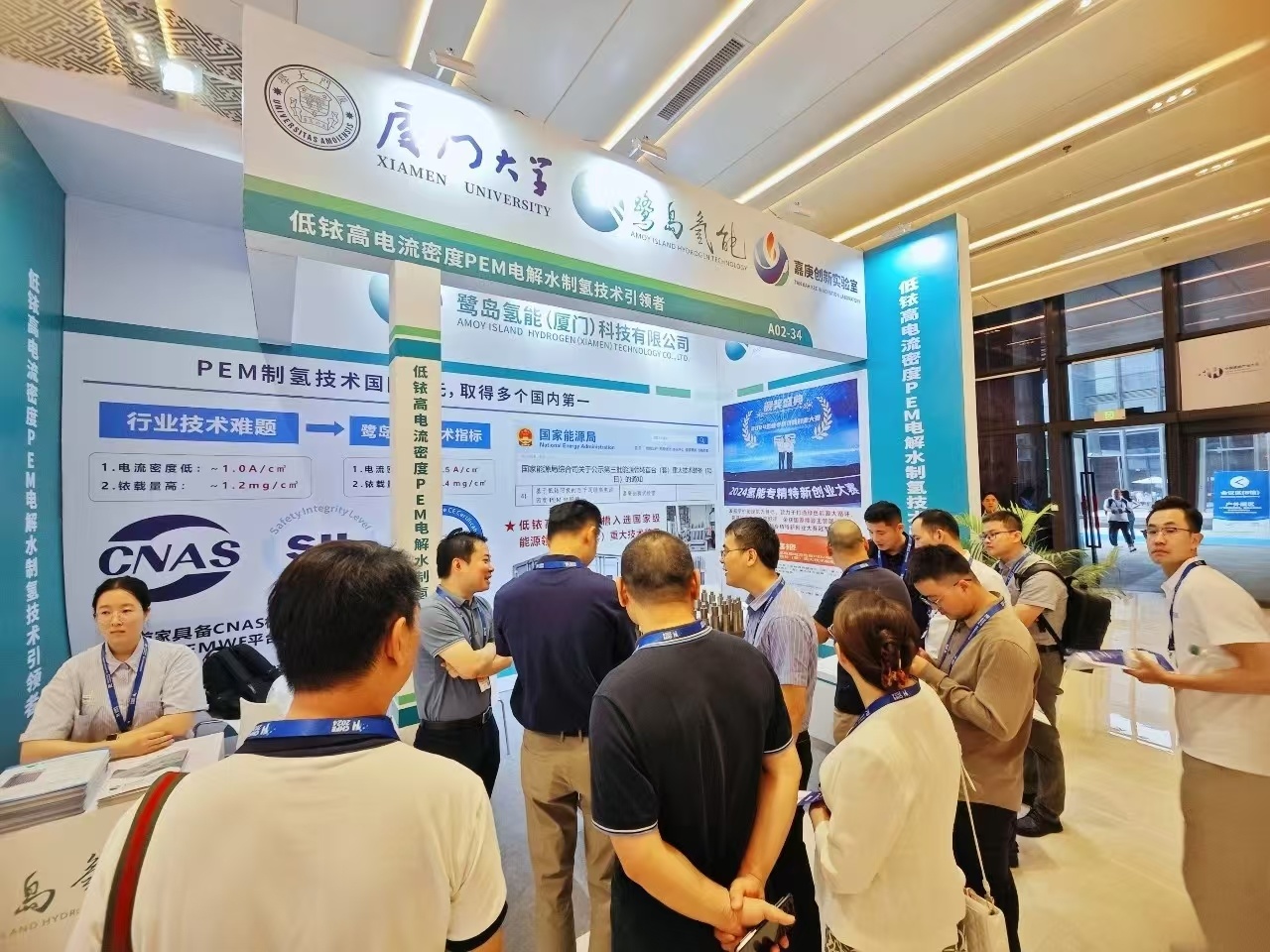

The new product made its debut at the 8th China (Foshan) International Hydrogen Energy and Fuel Cell Technology and Product Exhibition. Along with the new product launch, AihyTech also introduced the company profile, core products, and development plans. AihyTech, relying on its core technological advantages, independently developed a low-iridium, high-current density series of PEM electrolyzers (series products cover hydrogen production from 0-500 Nm³/h), and this product was selected as a major piece of equipment with key national energy technologies . The company's electrolyzer annual production capacity exceeds 1 GW, and it possesses a full-cycle industrial chain of electrolyzers, hydrogen production systems, core materials, and testing instruments. As of October 2024, the annual cumulative orders have exceeded 100 million yuan, and it won the championship in the 2024 Hydrogen Energy Specialized and New Enterprise Creation Competition.

Hydrogen energy is a strategic emerging industry that is currently a national priority. It is reported that by 2030, China's renewable hydrogen installed capacity will reach 100 GW, with PEM accounting for over 40%, and PEM electrolytic water hydrogen production will gradually become the "main force" of green hydrogen . The demand for PEM electrolyzers will experience explosive growth, with an estimated demand of over 10 billion yuan in the next 3 years. AihyTech is responding to the tide of energy transformation and industrial development, adhering to core technology research and development and breakthroughs, continuously developing more efficient, more worry-free, and lower-cost products to promote the affordability of green hydrogen and the large-scale commercialization of PEM, while also helping to solve the problem of renewable energy fluctuation power consumption, and promoting the healthy development of the hydrogen energy industry.

Room 701, Building 666-1, Lianxiang Road, Xiang'an District, Xiamen City

Copyright © 2023 Amoy Island Hydrogen Technology Co., Ltd.

Website Construction:China Enterprise Power Xiamen | SEO