- All

- Product Management

- Blog

- Introduction

- Corporate Outlets

- FAQ

- Corporate Video

- Corporate Brochure

Dialogue: A Decade of Dedication – Addressing the Critical Challenges of PEM Electrolysis from Technology to Market

Release time:

2024-11-19 09:53

Source:

The domestication and independent development of PEM water electrolysis equipment is crucial. If we cannot independently produce our instruments and core materials, the cost will be difficult to reduce, and we will be 'strangled' by foreign countries. In 2020, Tao Huabing returned from Singapore and, at a crossroads in his entrepreneurial journey, delved into the research of electrochemical materials. He spent over two years focusing on the most critical component of PEM water electrolysis hydrogen production equipment: the membrane electrode. In April 2022, with the support of the Tan Kah Kee Innovation Laboratory, Amoy Island Hydrogen Technology Co., Ltd. (hereinafter referred to as "AihyTech") was established.

At the "2024 Hydrogen Energy Specialized, Refined, and New Entrepreneurship Competition" held by the China Hydrogen Energy Alliance, AihyTech won first place, attracting widespread attention from the industry and market. From an initial project R&D team of five or six people, it has grown into a "champion" enterprise with over 70 employees. AihyTech has achieved full-chain R&D of PEM water electrolysis hydrogen production equipment and self-sufficiency in key materials, thanks to its world-class and domestic first-rate technological capabilities and key product indicators.

Applying what one has learned, transforming abstract technology into tangible reality.

Image: 2024 Hydrogen Energy Specialized, Refined, and New Entrepreneurship Competition Annual Champion

China's 14th Five-Year Plan set a goal of reaching a total installed capacity of 1200 GW for solar and wind power by 2030. As of July this year, China has achieved this goal six years ahead of schedule. In the face of such large-scale growth in green electricity in a short period, water electrolysis hydrogen production will become a key application scenario for green electricity consumption.

Currently, the main factor restricting the development of green hydrogen is cost. The cost of producing green hydrogen includes the electricity cost in the water electrolysis hydrogen production process and the cost of the water electrolysis hydrogen production equipment. Therefore, Reducing the cost of renewable energy generation and hydrogen production equipment are two key factors in achieving the industrialization and large-scale application of green hydrogen.“Because my research direction is electrochemistry catalysis in the research process, I have always wanted to promote the affordability of green hydrogen through efficient electrochemical hydrogen production technology.” With this vision and mission, Tao Huabing began to gradually build a team framework during his time in Singapore, and with Tao Yongbing, the current chief equipment engineer of AihyTech, he began to experiment and explore in materials and kinetics.

Tao Huabing has long been engaged in research on water electrolysis hydrogen production technology, integrating chemical reaction engineering with electrochemistry to form a unique research direction in electrochemical reaction engineering. During the COVID-19 lockdown in 2020, Tao Huabing returned to China after many setbacks, arriving in Xiamen for the first time and joining Xiamen University, where he met Academicians Zheng Nanfeng and Tian Zhongqun, and launched in-depth academic and industrial cooperation and exchanges. "Xiamen University is a leading institution in the field of electrochemistry in China and enjoys a very high international reputation, something I knew even when I was an undergraduate at Tianjin University." Therefore, after returning to China, he unhesitatingly chose to join Xiamen University and the Tan Kah Kee Innovation Laboratory.

Rapid Growth: From Blueprint to "First Set"

AihyTech, combining the more than ten years of technological accumulation and research results of Tao Huabing's team and Xiamen University and the Tan Kah Kee Innovation Laboratory, focuses on high-efficiency hydrogen production systems, breakthroughs in high-efficiency electrochemical hydrogen production technology, and the development of high-efficiency and low-cost electrolytic hydrogen production equipment. “At the beginning of entering the hydrogen energy industry, we comprehensively evaluated multiple water electrolysis hydrogen production directions. After careful comparison, we believe that the advantages of proton exchange membrane (PEM) electrolyzers in terms of efficiency, flexibility, and safety can more effectively solve the problem of green electricity consumption; in addition, the higher technical threshold and challenges of PEM hydrogen production technology match our team's technical background and problem-solving capabilities, allowing us to leverage our strengths. Therefore, we decided to focus our R&D on PEM water electrolysis technology and strive to overcome the technical challenges in this field.” Tao Huabing has always been confident in the team's technical capabilities.

“The most important thing is to apply what one has learned. If the knowledge gained and the research results cannot be transformed into practical technology and industrial applications, it is meaningless.” This is Tao Huabing's entrepreneurial aspiration, and it is what AihyTech has been doing.

Image: AihyTech engineers characterizing membrane electrode slurry

PEM hydrogen production equipment has not been able to achieve large-scale commercial production in the past, mainly because the cost is high, the performance of PEM electrolyzers is generally low, and a large amount of expensive materials is required for the same amount of hydrogen production. The catalysts on the membrane electrode rely on precious metal materials such as iridium, which are expensive, have low utilization rates, and have short lifespans.

At that time, China urgently needed to develop high-performance electrolyzers with independent intellectual property rights, focusing on breakthroughs in the preparation technology of core materials such as anode catalysts and membrane electrodes, to achieve high current density, high energy conversion efficiency, and high stability.

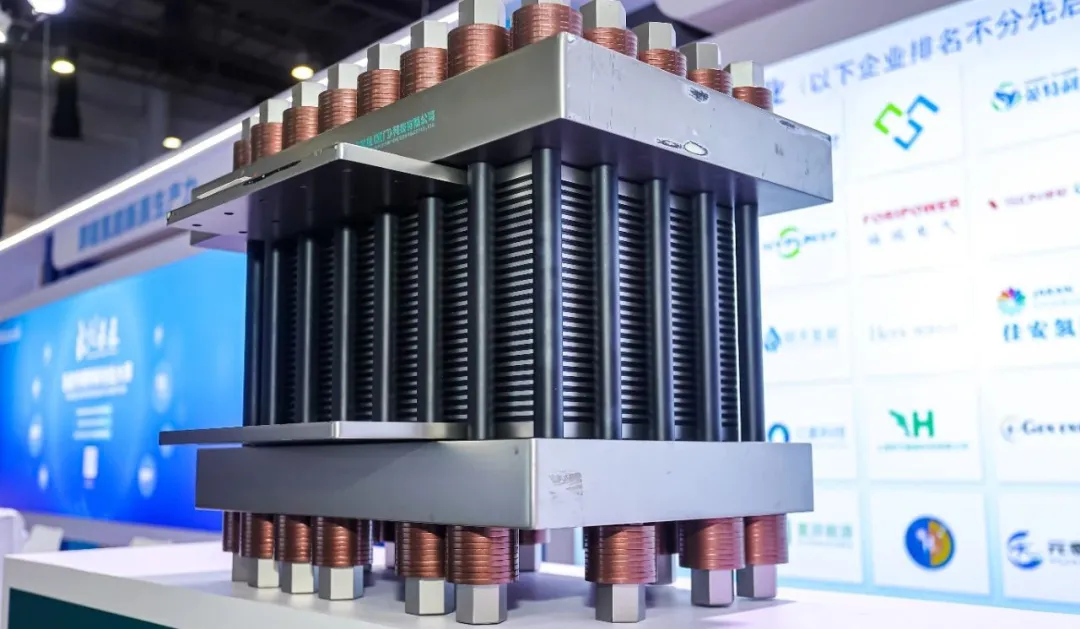

Image: China Hydrogen Energy Alliance at the Investment and Trade Fair

Displayed at the "Leading China Hydrogen Energy Industry Zone"

AihyTech Low-Iridium High-Current Density Electrolyzer

“The biggest challenge in increasing current density is solving the attenuation problem of PEM water electrolysis. We have conducted a large number of tests to solve its mechanism from the underlying logic. The reason for designing low-iridium high-current density is to consider the long-term application of PEM water electrolysis. Because China's iridium reserves account for only 0.2% of the global total, our goal is to reduce the iridium loading in low-iridium high-current density to less than 0.1 mg to cope with potential resource shortages in the future during large-scale applications. After numerous tests, we finally found that the attenuation is caused by the physical structure degradation of the catalytic layer formed by the catalyst. After finding this root cause, we redesigned a set of catalyst evaluation systems and carried out a large number of process improvements and optimizations to ensure the long-life operation of the low-iridium high-current density electrolyzer.”

Tao Huabing and his team members conducted nearly a thousand experiments before finally preparing a catalyst that met the conditions, reducing the amount of iridium on the membrane electrode material by 70%. At the same time, the effective utilization rate of iridium, hydrogen production efficiency, and equipment lifespan of the PEM water electrolysis equipment have not decreased but increased, truly solving the key problems for the PEM water electrolysis technology to enter the market and providing technical support for the team's transformation into an enterprise.

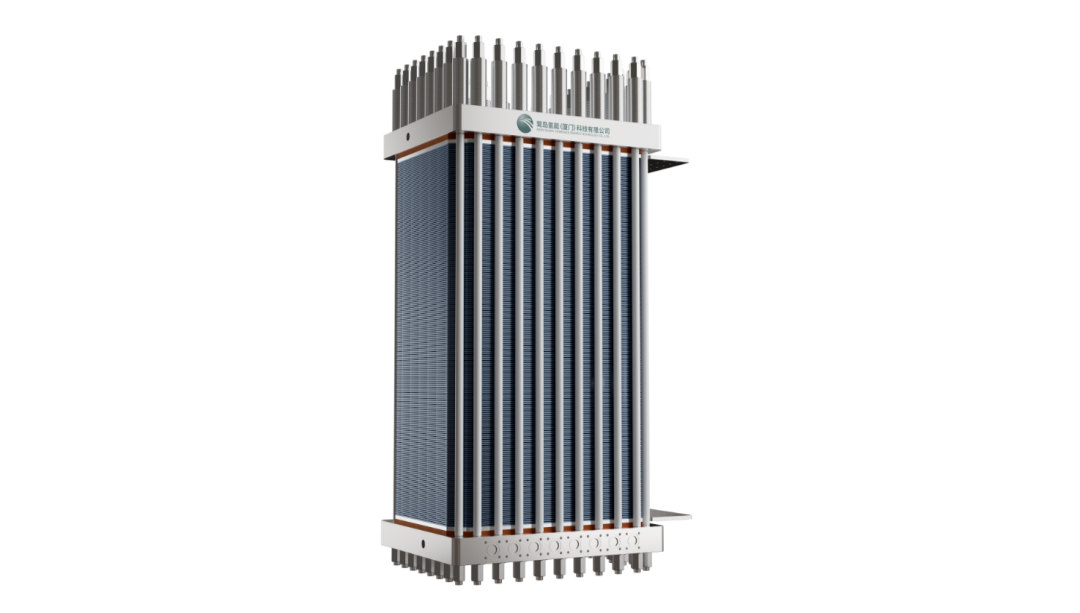

Image: AihyTech Low-Iridium High-Current Density Single-Stack 500 Nm³/h Electrolyzer

In April 2023, AihyTech independently developed the multi-channel PEM electrolyzer testing instrument obtained CNAS detection certification, and released high-performance megawatt-level PEM hydrogen production equipment; in October, the low-iridium, high-current density PEM electrolyzer was selected as the "first (set) major technological equipment in the national energy field." June 2024, AihyTech's megawatt-level series electrolyzers were officially put into operation at the hydrogen refueling station in Urumqi, Xinjiang. According to actual measurements and verifications, the relevant data has reached a leading domestic level; in October, AihyTech released a new generation of low-iridium, high-current density single-stack 500 standard cubic meter electrolyzer, pushing the domestic PEM water electrolysis hydrogen production technology towards larger specifications and lower costs.

「 Hydrogen」Road, full of thorns

Perseverance can achieve anything. Behind the rapid development and fruitful results are more than ten years of technological accumulation and the firm belief in perseverance and hard work.

“For so many years, I have been committed to the field of water electrolysis. For several years, water electrolysis was not so popular, and many people went to the much-anticipated fields of carbon dioxide reduction, nitrogen reduction, single-atom catalysis, etc. However, our research has been focused on the anode of water electrolysis for more than ten years, because it is also the most difficult part of the water electrolysis process.” Recalling the journey, Tao Huabing said.

During the R&D process, they also encountered repeated doubts, "Some people worry about the future restrictions on precious metals involved in PEM, whether it will become a mainstream technology in the future." However, after repeated discussions and verifications, Tao Huabing's team still focused on PEM water electrolysis technology. " In 2020, the gap between our domestic technology and foreign technology was still quite obvious. However, today, whether in terms of unit scale or technical parameters, we have reached the advanced level of Europe and the United States, and even in the research of anodes for water electrolysis, we have surpassed Europe and the United States. In witnessing the smooth progress of technology, our confidence in the future development of PEM technology is also constantly increasing.”

Figure | Megawatt-level PEM hydrogen production system

In the process of industrialization, Tao Huabing recalled that the most challenging aspect was the scaled-up production of electrolyzers. “At that time, time was tight and the task was heavy, and we faced the constraints of delivery time, but because we have always been doing forward research and development, we have never actually made such a large electrolyzer or such a large system. At that time, we were very worried that the products after scaled-up production would not meet the expected results. Fortunately, after the first generation of electrolyzers was produced, it basically reached the design performance, and after continuous iteration, its performance indicators have also been continuously improved, which gave us full confidence in the scaled-up production process.”

However, compared to the difficulties in the R&D and industrialization process, for Tao Huabing, who went from university to enterprise, entrepreneurship itself is even more difficult. “In the past, I only needed to focus on scientific research work, but now I also need to manage many aspects of company operations. As a novice entrepreneur, everything has to be learned from scratch. In this process, I found that my knowledge is very narrow, and I only know how to do research; but running a company requires not only technology, but also management, financing, and marketing, all of which I need to learn from scratch.” Tao Huabing said. “Sales is also a science, and our business model has also gone through a process of transformation from simply selling products to providing comprehensive application scenarios, which requires us to fundamentally change our way of thinking. We are no longer just processing or producing, but providing overall application scenarios that include our process technology. PEM water electrolysis hydrogen production is a newly developed technology in China. In practical applications and demonstrations, many customers are not professional R&D personnel in the water electrolysis field, and they often lack understanding of technical details and the acceptance of new products needs to be further improved. This requires us to focus on leading product technology while also designing detailed and easy-to-understand Application scenarios for customers. This shift in thinking from single-product research to customer-centric solution design is another level of challenge for us.”

There is a long way to go from scientific research results to market application. In the face of the rapid development of the hydrogen energy industry and the continuous influx of hydrogen energy companies and hydrogen energy talents, Tao Huabing said, “The hydrogen energy industry has a high threshold, and it is difficult to do technology and business, but the future prospects are undoubtedly very broad. For those who intend to cultivate in this industry, my suggestion is to be prepared for long-term investment and overcoming numerous difficulties.”

- THE END -

Pictures and text are from CHA Hydrogen Energy Alliance

Room 701, Building 666-1, Lianxiang Road, Xiang'an District, Xiamen City

Copyright © 2023 Amoy Island Hydrogen Technology Co., Ltd.

Website Construction:China Enterprise Power Xiamen | SEO