- All

- Product Management

- Blog

- Introduction

- Corporate Outlets

- FAQ

- Corporate Video

- Corporate Brochure

Research Progress | Academician Zheng Nanfeng and Associate Professor Tao Huabing's team explores new perspectives on PEM water electrolysis technology research and industrialization

Release time:

2024-07-03 09:28

Source:

Recently, Professor Zheng Nanfeng and Associate Professor Tao Huabing's team from the Tan Kah Kee Innovation Laboratory published a commentary article entitled "The gap between academic research on proton exchange membrane water electrolysers and industrial demands" in Nature Nanotechnology (DOI: 10.1038/s41565-024-01699-x), in-depth discussion of the key gaps between basic research and industrial applications of proton exchange membrane water electrolysis (PEMWE) technology, and providing some thoughts on future research directions.

Against the global backdrop of achieving carbon neutrality goals, PEMWE technology has attracted significant attention due to its unique advantages in converting large-scale renewable energy electricity into green hydrogen. However, despite substantial investment in basic research in this field, the translation of academic achievements into industrial-scale PEM electrolyzers remains slow. In particular, the reliance of PEM electrolyzers on precious metals such as iridium and platinum results in high costs, approximately 3-5 times higher than alkaline electrolyzers, severely hindering their large-scale application.

Against the global backdrop of achieving carbon neutrality goals, PEMWE technology has attracted significant attention due to its unique advantages in converting large-scale renewable energy electricity into green hydrogen. However, despite substantial investment in basic research in this field, the translation of academic achievements into industrial-scale PEM electrolyzers remains slow. In particular, the reliance of PEM electrolyzers on precious metals such as iridium and platinum results in high costs, approximately 3-5 times higher than alkaline electrolyzers, severely hindering their large-scale application.

Through a survey of nearly 3,000 related papers in the Web of Science database, the research team found that current academic research mainly focuses on the development of precious metal and non-precious metal catalysts, while relatively neglecting other key components of PEM electrolyzers, such as the catalyst layer (CL), bipolar plate (BPP), gas diffusion layer (GDL), and porous transport layer (PTL). This bias in research focus has led to some important technical issues being overlooked, thereby affecting the overall performance and cost-effectiveness of PEM electrolyzers.

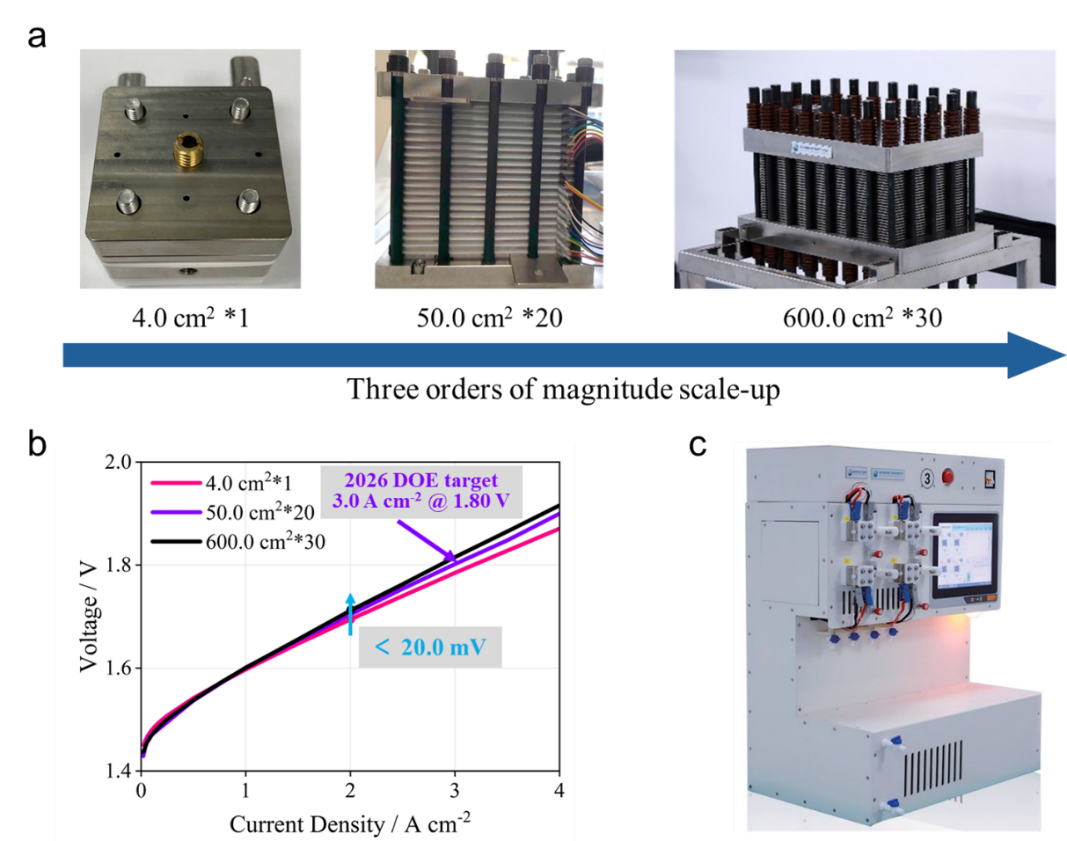

a. Scaling up PEM electrolyzers from a single cell to a 100 kW stack. The first set of advanced equipment certified by the National Energy Administration of China, "Low Iridium Loading High Current Density PEM Electrolyzer", has an iridium loading of 0.4 mg/cm² and a performance of 2.7 A/cm² @ 1.8 V.

b. Polarization curve of PEM electrolyzer during scaling up.

c. Four-channel PEM electrolyzer testing instrument.

The commentary article points out that academia is committed to pushing the limits of catalyst activity, while industry needs to strike a balance between cost, stability, and safety. Industrial applications require PEM electrolyzers to operate stably under fluctuating conditions for more than ten years, which places extremely high demands on the operating stability of the electrolyzers. However, academic research usually only conducts short-term stability tests, which cannot fully answer the long-term durability issues of concern to the industry. In addition, the commentary also emphasizes the balance between technical scaling up and scaling down during the scaling-up process. Due to the more complex synergistic effects of heat transfer, mass transfer, and charge transfer in large electrolyzers, simple scaling up often leads to significant performance losses. Therefore, constructing a small-scale electrolyzer research system that effectively simulates the actual operating conditions of electrolyzers and gaining an in-depth understanding of the different aspects affecting electrolyzer performance can provide important support for the scaling up and application of new technologies.

In the face of the challenges of renewable energy fluctuations, the commentary article proposes the need to expand the operating range of PEM electrolyzers. To reduce the cost of hydrogen, PEM electrolyzers need to operate stably and efficiently under low-load and overload conditions. Although hundreds of megawatts of PEM electrolyzers have been installed globally, there is still insufficient data on their performance under actual fluctuating power conditions, which points the way for future research.

The research results of Professor Zheng Nanfeng and Associate Professor Tao Huabing's team not only reveal the key gaps between academic research and industrial applications of PEMWE technology, but also provide insights and guidance for the future development of this field. By strengthening cooperation and communication between academia and industry to jointly address the challenges facing PEMWE technology, it is expected to promote the large-scale application of this technology at an early date and contribute to the achievement of carbon neutrality goals.

Professor Zheng Nanfeng, director of the Tan Kah Kee Innovation Laboratory, and Associate Professor Tao Huabing, head of the PEM water electrolysis hydrogen production project, are the corresponding authors of this article. This work is supported by the National Key Research and Development Program (2023YFB4004600), the Tan Kah Kee Innovation Laboratory (IKKEM) Science and Technology Project (RD2021010401), Fujian Provincial Science and Technology Projects (2022L3077, 2022H0004), and the State Key Laboratory of Solid Surface Physics Chemistry.

Room 701, Building 666-1, Lianxiang Road, Xiang'an District, Xiamen City

Copyright © 2023 Amoy Island Hydrogen Technology Co., Ltd.

Website Construction:China Enterprise Power Xiamen | SEO