LD-TS-10 PEM Hydrogen Production Test Equipment

Key words:

Products

hydrogen

LD-TS-10 PEM Hydrogen Production Test Equipment

Hotline:

LD-TS-10 PEM Hydrogen Production Test Equipment

LD-TS-10 PEM Hydrogen Production Test Equipment

Product Description

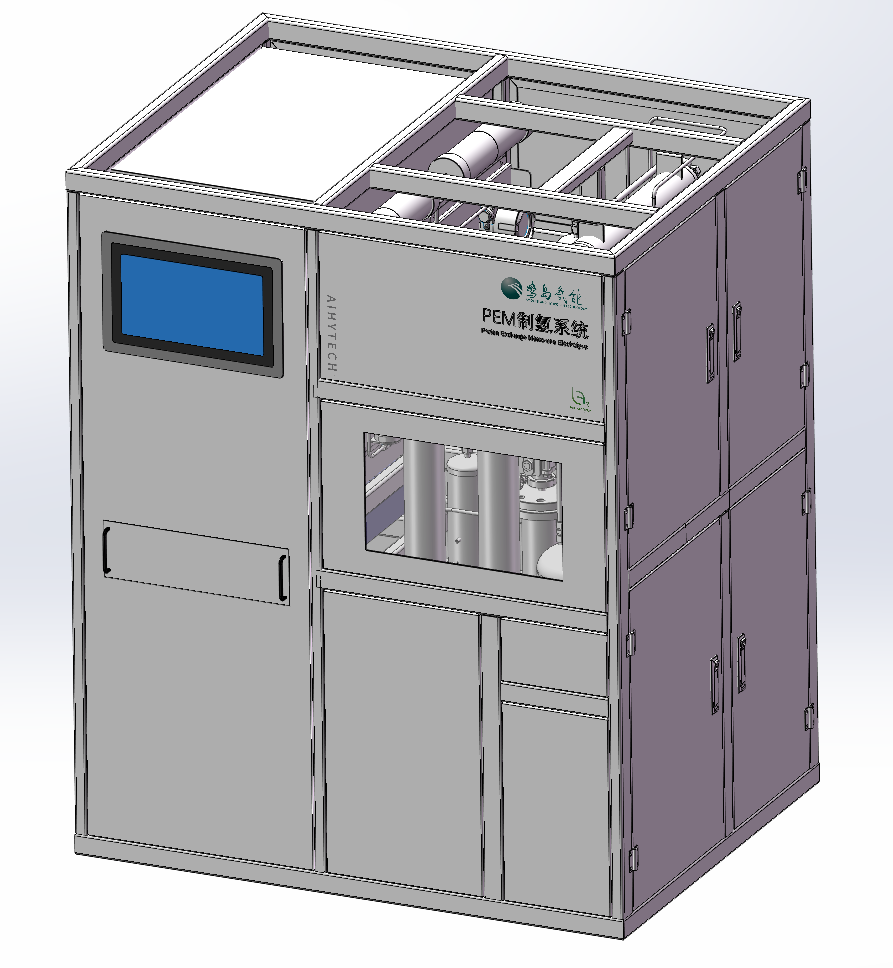

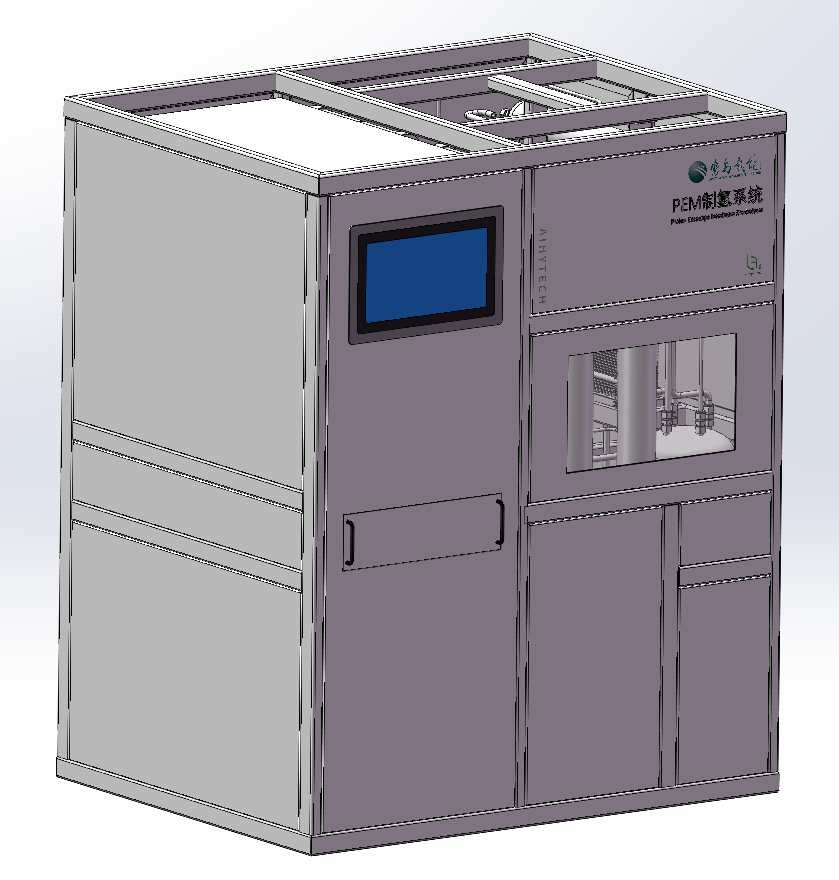

The LD-TS-10 10kW Hydrogen Production Testing Equipment is a high-performance device specifically designed for the working condition testing of PEM electrolyzers with a power rating of up to 10kW. It is suitable for a variety of testing scenarios, including catalyst performance testing, membrane electrode and proton exchange membrane (PEM) lifespan testing, operational performance testing of catalysts and PEMs, diffusion layer structure analysis, coating technology evaluation, precious metal loading optimization, and membrane electrode preparation processes. This equipment provides a comprehensive solution for the research and development of core materials and electrolyzers in PEM water electrolysis hydrogen production.

The system features automatic water replenishment, supports long-term durability testing (>5000 hours), and offers high safety, high precision, ease of operation, compact size, and mobility, making it suitable for laboratory and industrial applications.

Product Advantages

• High Precision—Ensures accurate detection of voltage, current, temperature, and pressure, guaranteeing reliable test results.

• Easy Operation—Simplifies operation procedures and enhances work efficiency.

• Compact and Mobile—Small in size, making it convenient for flexible placement and movement in laboratories or production environments.

• Comprehensive Testing Capabilities—Supports multiple testing modes to meet diverse R&D needs, providing a complete testing solution.

• Certified Quality—ISO certified, ensuring product quality and safety.

Technical parameters

|

Project |

Parameters |

|

Rated hydrogen production |

5 Nm3/h |

|

Rated current density |

2.0 A/cm2 |

|

Rated chamber voltage |

1.8 V |

|

Product hydrogen concentration |

99.999% |

|

DC power consumption |

4.3 kWh/Nm³ |

|

Comprehensive power consumption |

5.0 kWh/Nm³ |

|

Hydrogen pressure |

3.0 MPa |

|

Power adjustment range |

5-110% |

|

System life |

10 years |

|

Voltage inspection |

The detection range is 0-5 V, the detection accuracy is more than 10 mV, and the number of channels can be adjusted. |

|

Stack temperature |

Monitor the inlet and outlet temperature of the electrolyzer in the monitoring range of -20 to 150 °C, and the detection accuracy is ± 1°C. |

|

Gas temperature |

Multi-point temperature monitoring in the range 0-200°C with an accuracy of ± 1°C. |

|

Gas pressure |

Multi-point pressure monitoring in the range 0-4 MPa with an accuracy ± 1 kPa. |

|

Hydrogen concentration |

Three monitoring points in different locations, range 0-100% LEL, accuracy 3% LEL, resolution 1% LEL. |

|

Current inspection |

Accurate current control, detection range 0-110%, detection accuracy ± 0.1 A. |

|

Hydrogen humidity |

Hydrogen dew point monitoring range ≤-65℃, accuracy ±0.1℃. |

|

Ambient humidity |

Dew point monitoring ambient humidity, detection range -80~20°C, accuracy ±0.1°C. |

|

Hydrogen in oxygen |

The hydrogen detection range is 0-2%, and the detection accuracy is ±1%FS. |

|

Oxygen in hydrogen |

The detection range is 0-100 ppm, and the detection accuracy is ±10 ppm. |

|

Circulating water volume |

There are 2 monitoring points, and the detection accuracy is ± 0.1%. |

|

Loading rate(0-100%) |

≤8s |

|

Unloading rate(100%-0) |

≤8s |

|

System version |

The communication method adopts the network cable (RJ45) communication protocol (Ethernet), and the automatic control system version is the Siemens 1200 series. |

|

Visual design |

Arrange the visual windows properly. |

|

Data linkage |

The monitoring data is connected to the display to realize real-time linkage. |

|

Insulation resistance (positive and negative electrodes to the shell, gas and water circuit)(Ω/V) |

≥500 |

|

Ground resistance |

4 Ω |

|

Explosion-proof measures |

Flameproof instruments are adopted to install hydrogen leakage interlocks. |

|

Hydrogen leakage detection and measures |

Installation of a hydrogen leak detector. |

Application Scenarios:

• R&D and testing of core materials and electrolyzers for PEM water electrolysis hydrogen production.

• Performance evaluation and lifetime testing of materials such as catalysts, membrane electrodes, and proton exchange membranes.

• Research on coating technology, optimization of precious metal loading, and membrane electrode preparation processes.

• Educational and research purposes, providing a practical platform for students and researchers.

Related Products

LD-TS-1C-530 Single-channel Electrolyzer Test Station

Product Message